are you currently wanting to optimize your drilling operations and lower downtime? One of the more significant components impacting effectiveness may be the shaker monitor. Choosing the suitable display screen can substantially have an impact on mud movement, solids removing, and In general Charge-usefulness. This guideline will offer you the necessary information needed to make an educated determination and select an ideal shaker monitor for your personal specific demands, ensuring your drilling functions run easily and competently. As a number one shaker display screen producer, we understand the value of excellent and overall performance in this essential area.

Table of contents:

critical things to look at When choosing a Shaker display screen

differing kinds of Shaker Screens as well as their programs

How the proper Shaker display Can increase Drilling performance

crucial aspects to take into consideration When deciding on a Shaker monitor

Selecting the correct shaker screen calls for careful thought of a number of things. very first, the sort of drilling fluid getting used plays a major function. drinking water-primarily based muds require distinctive mesh sizes and monitor constructions in comparison with oil-primarily based muds. 2nd, the scale and sort of solids remaining removed are vital. Finer solids need finer mesh screens, but these can even be additional vulnerable to blinding. 3rd, evaluate the move charge and strain of your drilling fluid. superior move fees can place pressure over the display screen, possibly leading to untimely failure. lastly, Examine the shaker's compatibility with unique display sorts. Not all shakers can accommodate all monitor types, so confirming compatibility is crucial. contemplating these crucial variables will help you narrow down your options and select a shaker screen that optimizes your drilling operations. for instance, if you are employing a VSM300 shaker, examine choices like the corrugated a person-piece metal sheet substitute screens from dependable suppliers.

Different Types of Shaker Screens as well as their Applications

Shaker screens arrive in many different layouts, Just about every suited to diverse purposes. Woven wire mesh screens are a standard selection, providing a cost-effective Answer for eliminating an array of solids. Composite screens, built from several levels of mesh and support components, provide Improved toughness and finer filtration abilities. Pyramid screens, with their 3-dimensional surface, present elevated screening location and enhanced circulation potential. Hook strip screens are designed for quick installation and substitution, reducing downtime all through display alterations. Pre-tensioned screens are stretched and bonded to your frame, supplying constant stress and enhanced efficiency. Understanding the strengths and weaknesses of each and every style will let you decide on the best choice to your drilling setting.

How the appropriate Shaker Screen Can make improvements to Drilling Efficiency

the shaker screen proper shaker display screen collection right interprets to improved drilling efficiency. efficient solids removing helps prevent the buildup of solids from the drilling fluid, preserving its ideal Houses and lowering use on pumps as well as other tools. This, in turn, minimizes downtime for repairs and upkeep. A very well-chosen screen also optimizes mud flow, preventing tension drops and guaranteeing reliable drilling efficiency. In addition, productive solids Command lessens the quantity of squander created, lowering disposal prices and reducing environmental effects. By buying high-high quality shaker screens which can be customized to your precise drilling necessities, you'll be able to substantially improve effectiveness, reduce expenses, and boost the general accomplishment of your respective drilling operations.

In conclusion, deciding on the right shaker display is vital for optimizing drilling functions. By considering factors like drilling fluid type, solids size, movement amount, and shaker compatibility, you are able to find a screen that maximizes solids removing efficiency and minimizes downtime. comprehending the different sorts of shaker screens and their apps enables you to make knowledgeable selections which can be tailor-made in your specific requirements. As you move forward, take into account that buying high-quality shaker screens from a trustworthy shaker display screen company is surely an expenditure within the long-time period effectiveness and good results of the drilling functions. Don’t wait to consult with gurus to ascertain the most beneficial Resolution on your unique problems and optimize your drilling approach.

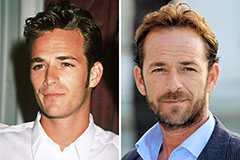

Luke Perry Then & Now!

Luke Perry Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!